By Martin Li, M.A., CRCST, CER, CIS, CHL

Introduction

Data analytics has emerged as a cornerstone in modern

healthcare, transforming how decisions are made at all levels of the industry.

For Sterile Processing Departments (SPD), the integration of data analytics is

not just beneficial but essential for improving operational efficiency,

ensuring compliance, and enhancing patient safety. This article delves into the

role of data analytics in healthcare sterile processing leadership

decision-making, with a particular focus on insights from an SPD educator's perspective.

The Role of Data Analytics in Healthcare

Data analytics involves the systematic computational

analysis of data to uncover patterns, correlations, and trends that inform

decision-making. In healthcare, data analytics is used to improve patient

outcomes, streamline operations, and reduce costs. The adoption of electronic

health records (EHRs) and other digital tools has exponentially increased the

availability of data, enabling healthcare leaders to make informed decisions

based on real-time information.

Importance of Data Analytics in Sterile Processing

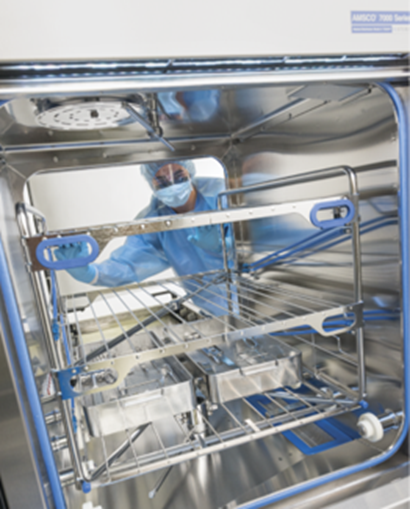

Sterile Processing Departments are critical to healthcare

facilities as they ensure that surgical instruments and other medical devices

are properly sterilized and safe for use. The complexity and high stakes

involved in SPD operations make data analytics an invaluable tool. By

leveraging data analytics, SPD leaders can enhance the efficiency of their

processes, maintain compliance with regulations, and improve overall patient

safety.

Data-Driven Decision-Making in SPD Leadership

From an SPD educator's perspective, data-driven

decision-making involves the use of data to guide leadership decisions,

identify areas for improvement, and implement evidence-based strategies. This

approach ensures that decisions are not based on intuition or anecdotal

evidence but on concrete data that reflects the actual performance and needs of

the department.

Enhancing Operational Efficiency

One of the primary benefits of data analytics in SPD is the

ability to enhance operational efficiency. By analyzing data on instrument

usage, turnaround times, and workflow processes, SPD leaders can identify

bottlenecks and inefficiencies. For instance, data might reveal that certain

instruments are consistently in high demand, leading to frequent shortages and

delays. Armed with this information, leaders can adjust inventory levels,

optimize instrument reprocessing schedules, and improve overall workflow efficiency

(Taipalus, 2023).

Ensuring Compliance and Safety

Compliance with regulatory standards is a significant

concern for SPDs. Data analytics helps ensure that all sterilization processes

adhere to the required standards and protocols. By tracking and analyzing data

on sterilization cycles, chemical indicators, and biological tests, SPD leaders

can quickly identify and address any deviations from established protocols,

thereby ensuring compliance and maintaining patient safety (Reed, 2024).

Predictive Maintenance and Equipment Management

Data analytics also plays a crucial role in predictive

maintenance and equipment management. By analyzing data on equipment

performance and maintenance history, SPD leaders can predict when equipment is

likely to fail and schedule preventive maintenance accordingly. This proactive

approach reduces downtime, extends the lifespan of equipment, and ensures that

critical devices are always available when needed.

Implementing Data Analytics in SPD: Challenges and

Solutions

While the benefits of data analytics in SPD are clear,

implementing these systems can be challenging. Common challenges include data

integration, staff training, and ensuring data quality. From an SPD educator's

perspective, addressing these challenges involves a multifaceted approach.

Data Integration

Integrating data from various sources, such as EHRs,

sterilization records, and inventory management systems, can be complex.

Effective data integration requires robust IT infrastructure and

interoperability between different systems. Educators play a crucial role in

facilitating this process by collaborating with IT professionals to ensure that

data flows seamlessly across platforms.

Staff Training

For data analytics to be effective, SPD staff must be

proficient in using data-driven tools and interpreting analytical reports.

Educators are responsible for designing and delivering comprehensive training

programs that equip staff with the necessary skills. This includes training on

data entry, data interpretation, and the use of specific analytics software.

Ensuring Data Quality

The accuracy and reliability of data are paramount in

data-driven decision-making. Educators must emphasize the importance of

accurate data entry and implement regular audits to ensure data quality. This

involves setting up standardized procedures for data collection and entry, as

well as conducting periodic reviews to identify and correct any discrepancies.

Case Study: Data Analytics in Action

To illustrate the practical application of data analytics in

SPD leadership, consider a case study of a mid-sized hospital that implemented

a data-driven approach to improve its sterile processing operations.

Background

The hospital faced challenges with instrument availability

and reprocessing efficiency. Frequent delays in instrument turnaround times led

to surgical schedule disruptions and increased costs. The SPD leadership

decided to adopt a data analytics solution to address these issues.

Implementation

The first step was to integrate data from the hospital's

EHR, sterilization records, and inventory management system. This integration

provided a comprehensive view of instrument usage, reprocessing cycles, and

equipment performance. The hospital also invested in training its SPD staff on

data analytics tools and techniques.

Results

Within six months of implementation, the hospital saw

significant improvements in its SPD operations. Data analysis revealed that

certain instruments were being underutilized while others were overused. By

adjusting inventory levels and reprocessing schedules, the hospital reduced

instrument shortages and turnaround times by 30%. Additionally, predictive

maintenance data helped the hospital avoid unexpected equipment failures,

further enhancing efficiency and reducing costs.

The Future of Data Analytics in SPD

The future of data analytics in SPD is promising, with

advancements in technology continually expanding the possibilities. Emerging

technologies such as artificial intelligence (AI) and machine learning (ML) are

expected to further enhance the capabilities of data analytics in healthcare.

Artificial Intelligence and Machine Learning

AI and ML can analyze vast amounts of data more quickly and

accurately than traditional methods. In SPD, these technologies can be used to

predict instrument demand, optimize reprocessing schedules, and identify

potential equipment failures before they occur. AI-driven analytics can also

assist in identifying patterns and trends that might not be immediately

apparent through manual analysis.

Real-Time Data Analytics

Real-time data analytics is another emerging trend that

holds great potential for SPD. By providing real-time insights into instrument

usage and reprocessing status, SPD leaders can make immediate adjustments to

their operations. This can lead to more responsive and agile decision-making,

further improving efficiency and patient safety.

Conclusion

Data analytics is a powerful tool that can significantly

enhance decision-making in healthcare sterile processing departments. From an

SPD educator's perspective, the integration of data analytics involves not only

the adoption of new technologies but also the development of skills and

processes that ensure effective data-driven decision-making. By addressing

challenges such as data integration, staff training, and data quality, SPD

leaders can leverage data analytics to improve operational efficiency, ensure

compliance, and enhance patient safety. As technology continues to advance, the

role of data analytics in SPD will only grow, offering even greater

opportunities for innovation and improvement in healthcare.

References

- Taipalus,

T. (2023). Data Analytics in Healthcare: A Tertiary Study. PMC. https://www.ncbi.nlm.nih.gov/pmc/articles/PMC9734338/

- Reed,

B. (2024). 3 Ways Big Data Will Ensure your Sterile Processing. LinkedIn. https://www.linkedin.com/pulse/3-ways-big-data-ensure-your-sterile-processing-department-brian-reed

- Data-Driven

Decision-Making for Health Administrators. (2022). Tulane University. https://publichealth.tulane.edu/blog/data-driven-decision-making/

- Reference

examples - APA Style. (n.d.). APA Style. https://apastyle.apa.org/style-grammar-guidelines/references/examples

- Citing

Sources: APA Citation Examples. (2024). WPI. https://libguides.wpi.edu/citingsources/apa_examples

- In-Text

Citations: Author/Authors. (n.d.). Purdue OWL. https://owl.purdue.edu/owl/research_and_citation/apa6_style/apa_formatting_and_style_guide/in_text_citations_author_authors.html