https://www.steris.com/healthcare/knowledge-center/

Surgical instruments and other reusable devices must be

effectively reprocessed so they are safe and functional for patient use. Before

an instrument can go through sterilization or high-level disinfection, it must

be cleaned. To ensure quality outcomes for the patient, the cleaning process

requires consistency and standardization.

Before reviewing the details of the process, it's important

to understand the distinction between "cleaning" and

"disinfection." Here are a few key definitions to know:

- Visible Soil: Blood, bone, tissue, and

inorganic soils such as dirt or dust

- Non-Visible Soil: Microorganisms, bacteria,

and viruses or chemicals

- Cleaning/Decontaminating: The removal of

contamination (often referred to as "soil") from a surface to

the extent necessary for further reprocessing or the intended use of the

surface. (ANSI/AAMI/ISO 15883-1)

- Disinfection: The antimicrobial reduction

of the number of viable microorganisms on a product or surface to a level

previously specified as appropriate for its intended further handling.

Most automated washer/disinfectors will accomplish this through thermal

disinfection.

- High Level Disinfection: The elimination of all

microorganisms in or on an instrument, except for small numbers of

bacterial spores.

- Sterilization: The process to eliminate

all viable microorganisms.

Next, let's review the steps in reprocessing surgical

instruments starting from point-of-use to manual cleaning and finally automated

cleaning using a washer/disinfector or ultrasonic cleaner.

STEP

1: POINT OF USE PRE-CLEANING

The first step in cleaning a surgical instrument is to

initiate pre-treatment. Instrument transport gels, like Pre-Klenz™ Point

of Use Preprocessing Gel, help initiate the cleaning process of

surgical, endoscopic, and robotic instruments immediately after use. Instrument

transport gels prevent the drying of bioburden, which can decrease the time

needed to manually clean the sink, as well as loosen soils.

STEP

2: MANUAL CLEANING OF SURGICAL INSTRUMENTS

After point-of-use pre-cleaning, instruments are

transported to the decontamination area of the Sterile Processing Department

(SPD) to begin manual cleaning. Manual cleaning should

be performed on all instruments but may be recommended as the preferred method

of cleaning for delicate or complex devices, such as endoscopes or

microsurgical instruments. Devices must be removed from the transportation

container and disassembled to expose all the surfaces to the cleaning process.

Always follow the device's Instructions for Use (IFU) for comprehensive

instructions for cleaning and disassembly.

For manual cleaning, a three bay sink

configuration is recommended. When using a three bay

configuration:

- The first sink bay will have instruments being pre-rinsed with cold

water to remove any pre-treatment product or blood.

- The second bay will have instruments immersed and pre-soaking in an

enzymatic or neutral detergent solution, then manually brushed using instrument

cleaning brushes. When a manufacturer’s IFU recommends

immersion of the device, cleaning in the sink should be done under the

water line to prevent exposure to microorganisms and aerosol generation,

especially when brushes are used to clean lumens. The cleaning

detergent should be low-foaming so staff can see clearly

into the sink to identify all instruments and prevent injuries from sharp

objects.

- The third sink bay is used for the final treated rinse. Depending on

the manufacturer’s recommended practices or a facility’s standards, the

final rinse water should be of a certain quality to help reduce any risk

to a patient of a device. Examples include controlled levels of water

hardness (to prevent spotting), chloride (to prevent device damage) and

microorganisms (to prevent cross-contamination).

STEP

3: AUTOMATED WASHING AND DISINFECTION OF SURGICAL INSTRUMENTS

After manual cleaning, most devices are then processed

through automated cleaning technologies such as ultrasonic cleaning systems and

washer/disinfectors.

Ultrasonic Cleaning

Ultrasonic cleaning is used for fine cleaning of

instruments with hard-to-reach areas like crevices, hinges, and lumens. After

manual cleaning, the devices should be sorted based on metal to prevent damage.

For example, aluminum instruments can react with stainless steel if immersed

together, causing etching, or replating to the devices.

Ultrasonic

cleaners work through cavitation where high-frequency sonic

waves create tiny bubbles on the surfaces of the instruments which eventually

implode. The implosion of these bubbles helps to dislodge soil from the surface

of the device. Low-foaming enzymatic cleaners can be used in ultrasonic

cleaners, assuming the foam does not interfere with the cavitation process.

After the ultrasonic

cleaning process, the instruments must be thoroughly rinsed with

either deionized or softened water.

Advantages of ultrasonic cleaning include a reduction of

time spent to clean complex instruments and removal of residual soil, however

not all materials or devices are compatible with this type of cleaning.

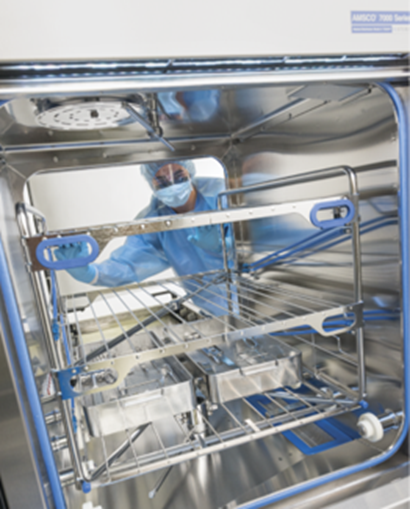

Washer/Disinfectors

The mechanical cleaning action of washer/disinfectors

relies on spray arm technology with pressurized water to help clean surgical

instruments or other reusable devices. The load inside a washer/disinfector is

exposed to a specific water temperature, chemical concentration, and flow rate.

The thermal rinse phase in a washer/disinfector provides a level of

disinfection. An optional drying phase can be added to reduce manual drying.

Successful cleaning using washer/disinfectors depends on

four parameters within the cycle:

- Time – If the cycle is too short, cleaning may not be achieved;

however, if it's too long, efficiency is compromised.

- Temperature – The temperature of the cycle wash depends on the

validated pre-programmed cycle and cleaning chemistries being used.

• When

enzymatic cleaning chemistries are used in washer/disinfectors, they typically

work best between 100-140 F/32-60 C with detergents typically being used in

ranges between 122-180 F/50-82 C. This can vary by manufacturer.

- Chemistry – The recommended cleaning chemistries are determined by

the washer/disinfector manufacturer and the IFUs for the devices being

processed. Other factors to consider in selecting a cleaning chemistry are

water quality and concentration of chemistry.

- Impingement – Representative of the mechanical force of spray arms.

If low impingement washer/disinfectors are used, a more aggressive

cleaning chemistry may be needed. High impingement washers rely on the

high pressure of the water to aid in soil removal.

Washer/disinfector

cleaning offers consistency and productivity, as parameter

control is easier. Staff must be properly trained on device loading to ensure

effective use.

CLEANING

FAILURES – RESIDUAL SOIL AND COMMON CAUSES

If after manual and mechanical cleaning soil is still

present, this can present several risks, with the most severe being the risk of

transmission to patients. In addition, residual soils left on devices can

damage the device's surfaces or ability to function correctly.

Possible Causes of Cleaning Failures

If soils are left on surgical instruments or reusable

devices after cleaning, common causes could be:

- Ineffective use of cleaning chemistries – Either the wrong chemistry

was used or an incorrect dilution rate

- Assembly of the instrument – The instrument was disassembled

incorrectly, which caused soils to become stuck in crevices or lumens

- Issues or failures with equipment – Problems with the mechanical

technologies, including misuse (i.e. overcrowding of trays) or equipment

failures

- Issues with manufacturer instructions – Instructions are either hard

to follow or contradict department procedures

CLEANING

VERIFICATION AND INSPECTION METHODS

After cleaning, all devices should be visually inspected

thoroughly with a lighted magnifying glass. In addition to routine visual

inspection, there are several methods that can be used to test cleaning

efficacy:

- Cleaning Indicators – Cleaning

process indicators verify that the washer/disinfector

cycle process parameters in all phases have the cleaning cycle have been

achieved. The indicator materials will break down or exhibit a color

change when the parameters have been successfully achieved.

- Cleaning

Verification – Beyond visual inspection, many hospitals

use a cleaning verification program such as ATP or Protein detection.

Protein is found in almost all surgical soils, and any living organism,

therefore detecting it on a "clean" device can help identify

gaps in cleaning procedures or hidden damage to devices.

GUIDELINES

FOR CLEANING AND DISINFECTING SURGICAL INSTRUMENTS

There are a variety of standards surrounding cleaning

surgical instruments and medical devices. Governing agencies, including

AAMI/ANSI, FDA, and AORN release guidelines for cleaning and disinfection.

Specific device IFUs should always be followed to ensure the device is

reprocessed according to the manufacturer. The specific standards/guidelines

around cleaning are spread throughout many standards, but the most common ones

are:

- ANSI/AAMI ST79, Comprehensive guide to

steam sterilization and sterility assurance in health care facilities –

most commonly referenced because of its detailed washer indicator

Appendix.

- ANSI/AAMI ST58, Chemical Sterilization

and High-Level Disinfection in Health Care Facilities

- ANSI/AAMI ST91, Flexible and Semi-Rigid

Endoscope Processing in Health Care Facilities – because of its

focus on the cleaning of complex endoscopy devices

IMPORTANCE

OF PROPERLY CLEANING REUSABLE DEVICES

Cleaning is an important step in the reprocessing of a

reusable device or surgical instrument. Both manual and automated cleaning can

be used and the methods will vary based on the device. Cleaning reusable

devices is important to prevent what we can see – including device damage – as

well as what we can't see like pathogenic microorganisms or transmissible

proteins. If devices are not clean, they cannot be properly sterilized, or

high-level disinfected.

No comments:

Post a Comment